The Sunkist® SunSort Grading Unit is a high speed, high-resolution electro-mechanical computer vision system. The computer vision system analyzes the complete surface of the fresh citrus fruit for a variety of quality attributes. These attributes include:

- Blemish (Defect) – light, medium, dark & total scar

- Color – average color, darkest green, or lightest color, peak color, variegation

- Size – average diameter, characteristic diameter or volume

- Shape – Aspect ratio and roundness

- Stem and Blossom

All functions use nominal values for setting break points that are determined by running test fruit and adjusting these values accordingly.

Blemish, Color and Size Electro-Mechanical Grader- (SunSort)

- The mechanical carrier is a patented spool / lifter / movable solenoid assembly unit that operates at a constant speed of 10 pockets per second per lane.

- Multiple 2,4, 6 or 8 lane frames, up to 24 lanes, can be integrated and programmed to perform the functions of a single machine.

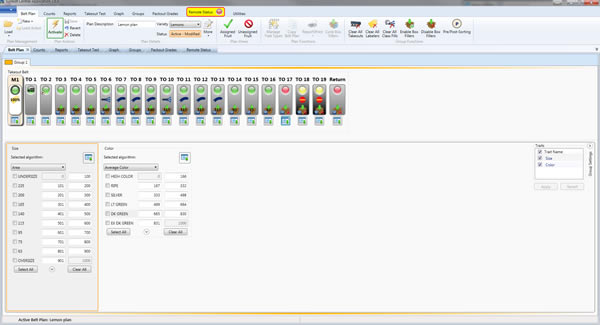

- The system utilizes a Microsoft Windows®platform for a fast/friendly operator interface, and elaborate reporting capabilities with over 20 reports to choose from.

- Technical support utilizing remote access software, which allows for rapid service support around the world.

- Custom reports using the latest in database technology.

- Each lane is integrated with the multiple lane system.

- Fruit can be sorted by Blemish, Color, Size, Variegation, and Long-Stem.

- This information is transmitted to a host computer that allows an operator to interface with the system.

- The operator chooses the various grading values to determine distribution of fruit on the multiple fruit drop points.

SunSort Mechanical System

- The minimum system length is 27′ 10″ which has capability for up to 5 drop points.

- The system can be extended with 45″,90″ or 110″ L. sections.

- Each module has an orienter motor and a main drive motor.

- Mitsubishi®C. inverters and programmer unit for main drive and orienter motors.

- PLC panel assembly with warning alarm and controls.

SunSort Optical System

- The grading system is run by a PC with monitor, keyboard, mouse and printer.

- Optical housing complete with camera assemblies.

- Commercially developed task specific cameras and lighting assemblies for optimum grading capabilities.

- Power Saving Function, which utilizes state of the art technology illumination for fruit detection.

SunSort Installation Requirements

- Access catwalks around and between the SunSort modules.

- All feed conveyor, pullout conveyors, recirculation conveyors, fruit rail extensions, and lane dividers.

- All support hardware consisting of a 4″ sq. tubing frame and legs for each module.

- Electrical control panel and field wiring to power SunSort modules.

- Power requirements – 3 phase power for motors, and power for PLC panel.